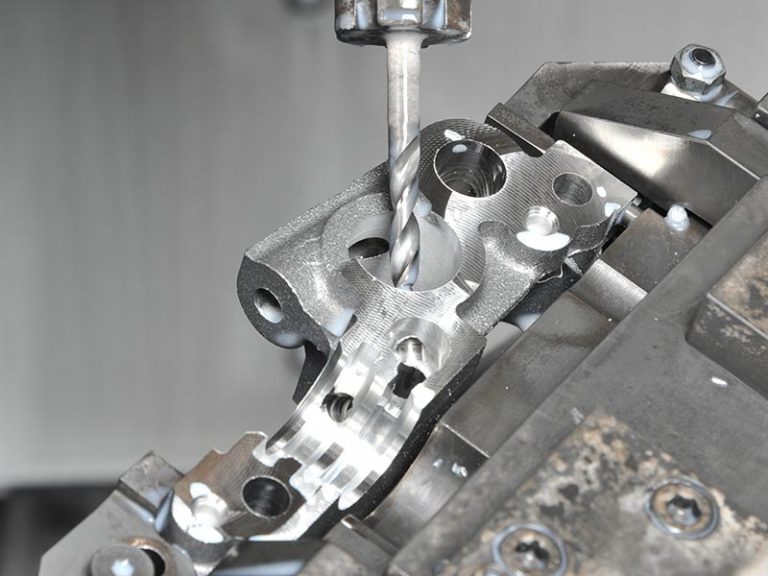

The process of aluminium die casting is used to make metal components with a complex shape. It is an inexpensive and practical form of manufacturing, which means it has become more popular in recent years. It’s the perfect way to get high quality castings while maintaining cost-effectiveness and efficiency. If you’re looking for information on custom aluminium die casting we’ve got some great posts on this blog that will help you out.

Why Should you Invest in Aluminium Die Casting?

The aluminium die casting process is a great way to create parts for cars, trucks, and other vehicles. There are many benefits associated with investing in custom aluminium die casting, making it an ideal choice for your business or company.

- Die casting is a process that allows for the creation of complex shapes

- It is cheaper and easier to manufacture products using custom aluminium die casting

- The quality of the casting is better than those created with other processes

- Aluminium die casting can be used in any industry, from automotive to aerospace

- Investing in aluminium die casting will allow you to produce more goods at a lower cost and higher quality.

What Type of Aluminium Metal Alloys are Used in Custom Aluminium Die Casting?

There are many different types of metal alloys that can be used in custom aluminium die casting. Each alloy has its own benefits and drawbacks that need to be considered when choosing the right one for your project.

- There are three types of alloys that can be used to produce aluminium die castings. The most common alloys include zinc, magnesium, and copper.

- Iron-based alloys provide the best strength but they rust easily and do not have good corrosion resistance

- Copper-based alloys offer better corrosion resistance than iron-based ones but don’t provide as much strength.

- Magnesium-based alloy is stronger than copper based one but has lower corrosion resistance

- Silicon is added to the alloys to improve their properties such as mechanical properties and thermal conductivity.

What is the Future for this Industry and What Does it Need to Thrive into the Next Decade?

These are questions that are asked a lot lately, and with good reason. This industry is changing faster than ever before and in order to stay relevant, it needs to adapt. So, what does the future hold for it? Let’s take a look.

- Innovation

- The move towards sustainability

- Consumer demand

- Emerging markets

- Technological advances

It is easy to see how aluminium die casting can be an effective process for production, and why it has been used by industry professionals for decades. The benefits of the custom aluminium die castings are not limited to cost savings or productivity, they also provide a means of producing durable parts with tight tolerances that will last through many cycles.